Problem:

Airbus wanted to design a new flight test engineer station (FTES). It needed to be modular to fit into all the brand’s aircraft, and a dozen examples would be produced.

The objective of Airbus was to be able to conduct short in-flight tests using an airliner from which a few seats had been removed.

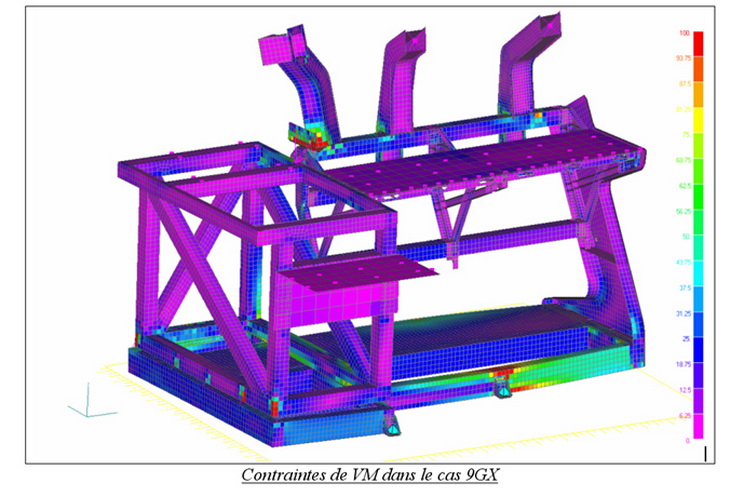

An FTES consists of the workstation, including the screens, and the remote calculator bays.

There were multiple constraints in order to reach the objective:

– The ergonomics of the station had to accommodate two test engineers while still simplifying use;

– The FTES needed to enter the aircraft through the door and be able to be assembled in less than half a workday by two fitters;

– The assembly of the FTES could not damage the interior of the aircraft, and its fastening in place needed to meet stability standards in the event of a crash.

The deadlines and cost objectives were tight—the prototype had to be delivered for certification in under one year.